What Is optical device Etching?

What Is optical device

Etching?

Laser etching may be a method that makes

marks on elements and product by melting their surface. it's a part of the

broader class referred to as optical device marking that additionally includes

optical device engraving and optical device tempering. extremely versatile, it

will be used with most metals.

To produce a raised mark, the shaft

delivers a high quantity of energy to atiny low space. As a result, the surface

of the fabric melts and expands. this may color the fabric in black, white or

grey.

Etching is most ordinarily wont to turn

out permanent markings like knowledge matrix codes, serial numbers, bar codes

and logos.

When Was optical device

Etching Invented?

The date optical device etching was

unreal is unknown however we all know that optical device engraving was

reported to be used for the primary time

in 1978. Since the 2 processes ar terribly similar (laser engraving involves

some level of melting), the origin of optical device etching is arguably a

similar as optical device engraving.

Here are a number of the key events that

LED to the invention of optical device etching as we all know it today:

1917 – physicist theorizes that

electrons will be created to emit light-weight of a selected wavelength in his

paper “On the scientific theory of Radiation”.

1951 – Charles onerous Townes conceives

the amplifier (microwave amplification by stirred emission of radiation), the

forerunner of the optical device (light amplification by stirred emission of

radiation). In 1954, he demonstrates that the amplifier works with a tool that

emits a wavelength of ≈1 cm.

1957 – Gordon Gould theorizes the

optical device. nearly at a similar time in 1958, Townes publishes a paper that

shows that masers might operate within the optical and spectrum. This results

in long patent disputes, with Gould solely receiving patents in 1977 and 1979.

In 1988, he receives royalties for the primary time once thirty years of

disputes.

1960 – the primary optical device is

built. It uses an artificial ruby crystal (its gain medium) to amplify

light-weight.

A diagram of the primary ruby optical

device. within the middle, a ruby crystal is employed as its gain medium.

1960 – the primary continuous shaft is

generated. this system is employed nowadays for applications like optical device

fastening and optical device cutting.

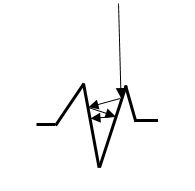

1962 – Q-switching, a way for

manufacturing periodic optical device

beams, is unreal. periodic beams reach

higher peak powers than continuous beams and ar used nowadays for optical

device etching, optical device engraving likewise as several different

industrial applications.

1964 – The Nd:YAG optical device is

unreal. In today’s producing, variants of this optical device are used for

optical device etching, optical device cutting and optical device fastening.

1964 – The greenhouse emission optical

device is unreal. Today, it's used for applications like optical device marking

and optical device cutting.

1978 – the primary optical device

engraver, though in its primitive kind, is purchased. it's wont to produce

works of art on wood.

1996 – the primary software package

designed specifically for lasers is made. Computers are eventually directly

integrated into optical device engraving machines.

From that time on, optical device

etching and optical device engraving began being employed additional wide to

engrave personal things and to implement trendy traceability in production

lines.

How will optical device

Etching Work?

All optical device marking strategies

have one factor in common: the shaft is periodic, emotional sudden bursts of

energy at specific intervals. inside one second, a one hundred periodic optical

device will unleash 100,000 pulses. every pulse contains one millijoule of

energy and might reach ten,000W of peak power.

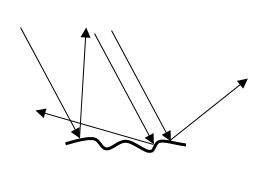

Since optical device etching a metal

needs less energy per space than engraving it, pulses are additional distant

from each other, as shown below.

when the beam hits the surface, the fabric absorbs its energy, changing it into heat. whereas the fabric surface reflects most of the beam’s energy, it additionally absorbs and converts a part of that energy into heat. For optical device etching to occur, the fabric should absorb merely enough energy to soften its small surface and build it expand.

When the beam’s energy is reworked into heat, the temperature of the fabric will increase. At such a high heat, the surface becomes malleable, permitting its form to vary.

Melting

Point of various Metals

Material Melting

purpose

Aluminum 6061 585°C

Aluminum 380 566°C

Carbon Steel 1425—1540°C

Lead 327.5°C

Magnesium 650°C

Stainless Steel Grade 304 1400—1450°C

Stainless Steel Grade 316 1375—1400°C

As the material melts and cools down

inside milliseconds, localized changes occur on the surface. Surface roughness

changes, making permanent markings.

What do changes in roughness look like?

Let’s investigate enlarged pictures taken exploitation AN microscope.

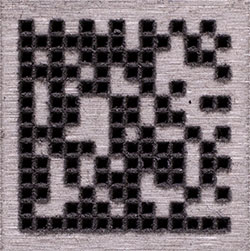

The

clean atomic number 13 before the optical device etching method, viewed

exploitation AN microscope. The surface is very swish. Cells of a knowledge matrix code incised on AN atomic number 13

surface, viewed exploitation AN microscope. a part of the surface shows diffuse

reflections caused by tiny changes in roughness. Another a part of the surface

shows absorption caused by chaotic changes in roughness.

As you'll see, surface roughness is for

good affected. Color changes seem as a results of totally different patterns on

the surface. For high-quality markings, the black and white colors supply the

simplest contrasts.

Of course, the method is optimized for

every application and therefore slightly totally different. If you have got

specific necessities, the simplest thanks to verify however the etching method

works for your application is to raise a optical device knowledgeable.

If you wish to any explore the physics

behind optical device technology, you'll additionally watch free academic

videos created by the university.

What’s the distinction

Between optical device Etching and optical device Engraving?

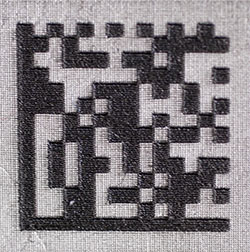

A data matrix code that was created with

optical device etching, forming a raised mark. a

knowledge matrix code that was created with optical device engraving, forming a

deep mark.

Laser Etching optical device Engraving

Laser etching is quicker, however

optical device engraving is additional sturdy. this is often as a result of

reaching a material’s freezing point (laser etching) needs less energy than

vaporizing it (laser engraving). Deep optical device engraving might even need

many optical device passes and inevitably even longer.

On the opposite hand, the holes mamma

with engraving have a far better protection against abrasion than the elevated

marks fashioned with etching. In fact, the optical device etching elevation

will reach up to eighty microns whereas the optical device engraving depth will

reach five hundred microns.

Laser etching stands out once it

involves making high-contrast markings. Whereas optical device engraving solely

creates black marks, optical device etching will be wont to produce each black

and white marks. For this reason, optical device engraving is typically

employed in combination with optical device etching to form high-contrast

engravings.

Etching is usually higher than engraving

unless you wish high resistance to abrasion. If you continue to can’t decide

that is best for you, we’ve ready a piece of writing to assist you select

between etching and engraving. otherwise you will raise a optical device

knowledgeable.

Watch this video to check each optical

device engraving (dark markings) and optical device etching (pale markings).

Is optical maser Etching

Permanent?

Yes, optical maser etching is permanent.

A optical maser carved mark can stay legible for the half’s helpful life with

higher readability than alternative direct part marking technologies. In fact,

optical maser etching will stand up to non-abrasive treatments as well as

e-coating, powder coating and warmth treating.

But grasp that optical maser etching has

its limitations. Abrasive treatments like shot blasting and sandblasting

generally take away optical maser carved marks. to keep up readability when

abrasive treatments, you wish to mark work pieces with shot blast resistant

optical maser engraving.

What Materials will be

carved with a Laser?

Laser etching could be a versatile

method which will be used with nearly any metal. the subsequent list is

non-exhaustive:

- Aluminum

- Anodized atomic number 13

- Lead

- Magnesium

- Steel

- Steel untainted

- Zinc

For data on marking completely different

materials, contact the optical maser knowledgeable.

What colors will be carved

with a Laser?

Laser etching will generate black, white

and reminder grey. For high-quality markings and half traceability, black and

white offers the simplest distinction. Here’s however optical maser etching

creates those colors:

Diffuse

reflections produce white Absorption

creates black

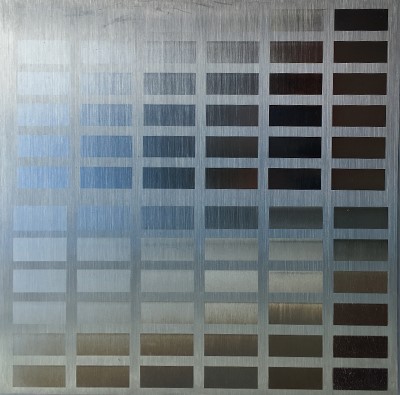

Laser tempering, a unique marking

method, will produce a wider vary of colors on steel and stainless-steel. By modulating

the optical maser parameters, completely different colors will be created, as

shown within the following photos. Examples of colors created with optical

maser tempering, shown on a color matrix. samples

of colored logos created for an illustration at a Solutions event.

How Fast Is optical maser

Etching?

Laser etching is quite doubly as quick

as engraving and tempering, creating it the quickest optical maser marking

method. to extend the etching speed, you'll use systems with higher optical

maser powers. for many marking applications, the most optical maser power

you'll want is 100 watt. Higher power lasers also are out there if required.

A system of equal power will print

quicker than another if it's designed with higher optical elements and has

optimized optical maser parameters. Our LXQ Series could be a typical example

of this. Speed tests have tried that it's the quickest optical maser marker for

metals.

Other than that, the marking speed

additionally depends on the kind of fabric, the scale of the symbol and its

colors (etching white marks is quicker than black marks). the subsequent

resources give you with samples of marking speed:

- Laser Marking Performance for atomic

number 13

- Laser Marking Time Estimate for

Industrial Applications

What sorts of optical

masers will Do Laser Etching?

Only fiber optical masers will be used

for laser etching. this can be as a result of etching could be a method used

with metals, that react higher to fiber lasers. In fact, the optical maser you

wish depends on the kind of fabric you wish to print, not on your marking

method.

But why specifically Does one want fiber

lasers to print metals? Bear with U.S.A., the solution is technical.

Lasers unharness energy by emitting

optical maser beams of specific wavelengths. once the beam hits the surface,

the fabric reflects most of its energy. The remaining energy is absorbed and

regenerate into heat. For optical maser etching, the fabric should absorb only

enough energy to soften.

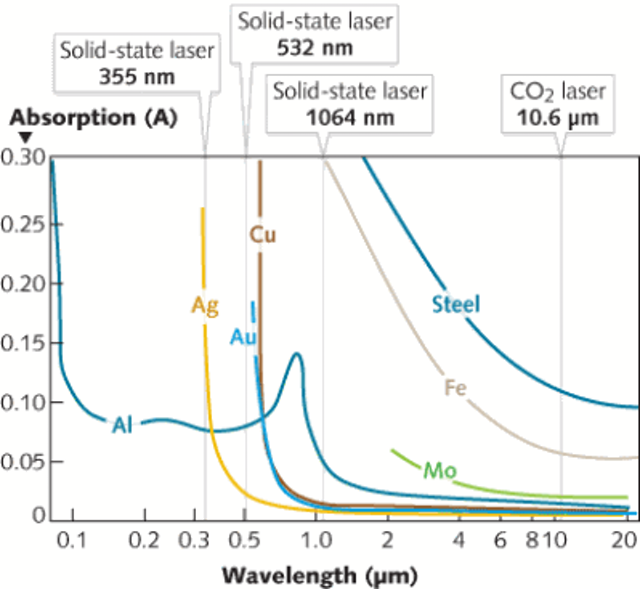

Now, fiber and greenhouse emission

lasers generate completely different wavelengths, and every material

absorbs/reflects these wavelengths otherwise. to maxmize the energy transfer

from the beam of light to the fabric, you wish the correct wavelength.

As you'll see within the following

graph, metals absorb the fiber laser’s wavelength (1064 nm) additional

expeditiously than the greenhouse emission laser’s (10.6 µm). For this reason,

the fiber optical maser (a style of solid-state laser) could be a better option

once marking metals.

A graph that shows the absorption rate

of metals for a spread of wavelengths. The wavelengths of solid-state lasers

(which embrace fiber lasers) and greenhouse emission lasers also are known

within the graph. a number of the metals whose spectrum is shown embrace atomic

number 13, steel, and iron.

Original work revealed in optical maser

Focus World reprinted courtesy of Endeavor Business Media, LLC.

How Much will a optical

maser Etching Machine Cost?

It’s exhausting to place a value that

covers all solutions for optical maser etching, particularly as a result of the

worth varies plenty from one company to a different. however we are able to

provide you with a plan of the prices concerned.

The optical maser system itself isn't

that pricey, with higher costs for producing applications and lower costs for

fewer serious applications. the worth you pay additionally depends on the

extent of automation you wish.

·

Tabletop lasers, or desktop lasers,

square measure the smallest amount pricey solutions. they're meant for native

stores World Health Organization need to engrave personal things like

jewellery, trophies and guns. as a result of marking isn’t performed in

Associate in Nursing enclosure, sporting optical maser safety specs is needed.

·

Manual workstations square measure

dearer than work surface optical masers as a result of they embrace a Class-1

laser enclosure that keeps the operator 100 percent safe. this sort of optical

maser is good for batch marking.

·

Semi-automated workstations feature a

rotary table that supports the operator, permitting the marking operation to be

performed in hidden time. this sort of digital computer is employed for inline

optical maser marking (the operator should follow the assembly flow). it's additionally

used for batch marking.

Fully automatic optical maser machines

square measure the foremost pricey solutions. they're meant to be integrated in

high-volume production lines that use robots or conveyor systems, like those

found in smelting plants, casting plants, and assembly lines.

What Makes Some Lasers

additional Expensive?

The examples that follow can assist you

perceive the worth gaps between lasers from completely different firms.

·

Some optical maser machines provide no

environmental protection whereas others have informatics ratings, protectively

against dirt, water and alternative contaminants that would break your system

over time.

·

Some optical maser systems square

measure made from low cost optical elements that generate low-quality markings.

alternative lasers use higher quality elements that improve sturdiness, speed,

distinction and exactness.

·

Some lasers square measure fencelike in

plastic casings which will simply break. Others square measure fencelike in

durable gilded frames that stand up to direct shocks and shield the inner

elements.

Before shopping for the optical maser,

you should:

·

Discuss your application with the optical

maser knowledgeable World Health Organization will advise you.

·

Ask however the merchandise is

completely different than the competition’s.

·

Request a sample marking.

How does one Implement

optical maser Etching?

To implement optical maser etching

within and outdoors production lines, Laser offers optical maser marking

machines (for commonplace solutions) and OEM optical maser markers (for custom

solutions with system integrators).

We know that every project has specific

needs. If you have got queries on however optical maser etching is enforced, we

are able to assist you. All you wish to try and do is raise our consultants.

Comments

Post a Comment