The utilization of laser in piece of clothing fabricating

The utilization of laser in piece of clothing fabricating: an outline

Abstract

Laser is being employed in garment industry from nineteenth century for numerous garment producing applications. There square measure many blessings of victimization optical device over the standard processes in cutting, engraving, embossing, denim weakening and alternative applications. additionally, product injury potential is reduced, no/less consumables square measure required and no drawback of harmful by-product disposal as found in some processes. Today’s optical device instrumentality may be a results of continuous analysis and development of earlier product, that has undergone many changes. The initial optical device systems were cumbersome, laborious to run and tough to keep up. However, the fashionable optical device systems square measure easier operating and maintenance. moreover, the sooner systems were committed a lot of questions of safety and required the gasses to be perpetually replenished. The garment manufactures round the globe ought to take the advantage of optical device application within the post multi-fibre agreement regime to form their product a lot of competitive. This review focuses on the technology of optical device together with numerous classifications. additionally it includes the applications of optical device in garment producing, their potential hazards and health connected considerations.

Introduction

Laser is being employed in garment industry from ninenteenth century. Recently the employment of optical device in garment industry is increasing in cutting garment patterns, patterning designer neckties, 3D body scanning, denim weakening and engraving animal skin (Nayak and Khandual 2010; Istook and Hwang 2001; Simmons and Istook 2003; Ortiz-Morales et al. 2003; Ozguney 2007; Bahtiyari 2011). the most important reasons for wide application of optical device in garment industries is also thanks to reduced value, flexibility and anti-counterfeiting (Kovacs et al. 2006; Tarhan and Sarıışık, 2009; Yuan et al. 2012). for instance the design of high-end tie producers square measure digitally hold on instead of physical patterns to lower the thieving risk. once required, the digital patterns square measure regenerate into physical samples victimization lasers (Lucas et al. 2015; Kan 2015). Recently, the appliance of optical device in denim engraving is increasing quickly for worth addition by commutation the normal denim-distressing technics, which can take the denim phase to a height of sophistication that may ne'er be realized by non-laser strategies (Kan 2014a). The distinctive nature of the garment producing trade wants optical device applications, which mixes performance with reduced value by eliminating the handling systems utilized in non-laser workstations.

Laser is associate energy supply, whose

intensity and power is exactly controlled. The shaft of light is centered to a

desired object at specific angle looking on the appliance. optical device will

facilitate to chop a spread of objects starting from versatile cloth to rigid

and robust metal (Belli et al. 2005; Ondogan et al. 2005). optical device

instrumentality are getting wide common in textile, animal skin and garment

industries thanks to the advantage of accuracy, efficiency, simplicity and also

the scope of automation (Kan et al. 2010; metal et al. 2010; Sutcliffe et al.

2000). for instance the standard cutting tools like band blades, discs and

mutual knives suffer from the constraints particularly on delicate materials

because the cutting force will displace the fabric, which might cause

inaccurate cutting (Nayak and Padhye 2015b). the normal cutting strategies

usually need associate operator with full attention (Vilumsone-Nemes 2012).

Hence, there's a trade-off between the most speed of cutting and also the

accuracy. additionally, alternative limitations embody elaborateness of the cut

parts, tool longevity and machine period of time throughout tool pairing. These

limitations don't seem to be gift in optical device devices, that helps to

realize improved potency and reduced value.

Laser is associate energy supply, whose

intensity and power is exactly controlled. The shaft of light is centered to a

desired object at specific angle looking on the appliance. optical device will

facilitate to chop a spread of objects starting from versatile cloth to rigid

and robust metal (Belli et al. 2005; Ondogan et al. 2005). optical device

instrumentality are getting wide common in textile, animal skin and garment

industries thanks to the advantage of accuracy, efficiency, simplicity and also

the scope of automation (Kan et al. 2010; metal et al. 2010; Sutcliffe et al.

2000). for instance the standard cutting tools like band blades, discs and

mutual knives suffer from the constraints particularly on delicate materials

because the cutting force will displace the fabric, which might cause

inaccurate cutting (Nayak and Padhye 2015b). the normal cutting strategies

usually need associate operator with full attention (Vilumsone-Nemes 2012).

Hence, there's a trade-off between the most speed of cutting and also the

accuracy. additionally, alternative limitations embody elaborateness of the cut

parts, tool longevity and machine period of time throughout tool pairing. These

limitations don't seem to be gift in optical device devices, that helps to

realize improved potency and reduced value.

Laser cutting with process

speed, high exactness, easy operation and alternative blessings, thus in most

industries is wont to, however it's within the article of clothing trade,

animal skin process plays a unique role, will quickly cut animal skin graphics

and draw precise article of clothing model (Potluri and Atkinson 2003; prepared

et al. 2001). The advantage of optical device cutting operations involve

extremely collimated beam that may be centered to a awfully fine dot of very

high energy density for precise cutting. apparel industry listen to the scale

of the garment once process exactness, the aim is to realize high potency,

exquisite trade, it's higher than the normal manual cutting by spectrum.

Although there square measure many

applications of optical device in attire producing, there square measure

restricted publications on this. Hence, a shot was created within the current

article to perform a radical review that covers numerous applications and up to

date developments in optical device that may give pointers for future directions.

additionally, a scientific description has been done on the technology of

optical device together with numerous styles of optical device. additionally,

this review includes the applications of optical device in garment producing,

their potential hazards and health connected considerations.

Laser technology

LASER is light-weight

amplification by stirred emission of radiation. optical device is Associate in

Nursing electromagnetic wave, made by the atoms thanks to energy states area

unit modified in some materials (Dowden 2009). The atoms promoted to higher

energy states emit optical device within the variety of light-weight by the

method referred to as “stimulated emission”. later, this optical device is

being amplified in an exceedingly appropriate lasing medium with the assistance

of mirrors. the ultimate optical device delivers from the instrumentation as a

stream almost like light-weight. the color of the optical device depends on its

wavelength. the foremost wide used unit accustomed categorical the wavelength

of a optical device is in micromillimetre (nm).

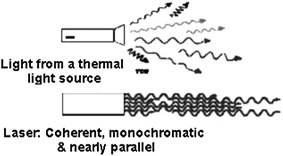

Laser light-weight (Fig. 1) emitted from a

optical device has four elementary characteristics: Intensity, Coherency,

Monochromaticity, and readjustment, that distinguish it from natural light-weight.

A high energy concentration per unit space of the beam is gift within the

optical device. A light beam may be of terribly high intensity with 1–2

millimeter of beam diameter Associate in Nursingd an output power of some

milliwatts (mW). All the lasers don't seem to be powerful in spite of the

sunshine with high intensity as intensity is calculable from the ability

output/area.

From Fig. one it may be

determined that the normal light-weight (from a thermal source) is incoherent,

i.e., light-weight waves area unit generated at totally different times and

propagate altogether doable directions indiscriminately. However, optical

device is coherent as shown within the figure thanks to the waves area unit in

section whereas they propagate. normal light-weight consists of all the colors

within the visible region, however optical device light-weight is of one color

or monochromatic. The coherent nature additionally to the monochromaticity

leads to extremely collimated optical device. As all the waves propagate in

same innovate parallel lines, there's virtually no divergence as determined in

light-weight. This property of optical device helps in achieving high intensity

even once travel a protracted distance. The energy concentration of the beam

may be exaggerated by manifold once the beam is concentrated as a degree with

the assistance of lens system.

For the assembly of the

light beam a lasing material is stirred with discharge in an indoor

instrumentality. variety of partial mirrors facilitate in multiple internal

reflections that result in get the required coherency and power output. Mirrors

or different optical devices facilitate in focusing the optical device to a

lens, that then reflects the optical device to the operating zone. so as to

modify the cutting action by a optical device off from the sting, it ought to

be punctured before the optical device cut employing a dynamical periodical

light beam.

Classes of lasing media

A substance, which might be

excited by input energy, is termed a lasing media. The lasing media have the

power to remain in an exceedingly constancy state. it's usually clear to

light-weight. The substance used as lasing media may be a solid, gas, liquid

dye or semiconductor. Solid lasing media is employed for manufacturing

solid-state optical device. thanks to the high density of lasing atoms,

solid-state lasers will generate higher power output per unit volume compared

to the gaseous-state lasers. one gas or airlike mixture may be accustomed

manufacture gaseous-state lasers. Gaseous-state lasers area unit made by

passing the electrical discharge within the airlike lasing medium. the foremost

common variety of airlike optical device is made from helium–neon (He–Ne). This

optical device is especially employed in teaching laboratories, at construction

sites and supermarkets.

Liquid dyes may also

manufacture optical device by mistreatment ultraviolet (UV) light-weight. These

liquid dyes may be ready by dissolving the solid dye particles in appropriate

solvent. The dyes and solvents with similar energy levels area unit

hand-picked, that facilitate to make a time for achieving high energy output

with wavelengths of light. higher tunability is that the distinctive feature of

a dye optical device, that distinguishes it from the solid optical device. one

dye produces one wavelength whereas dyes may be mixed to get a variety of

wavelengths. Semiconductors may also be accustomed manufacture optical device

with the assistance of electrical discharge. These lasers area unit defined by

their potency, miniature size and sturdiness.

Laser classification supported hazards

Since the first Nineteen Seventies, lasers were being classified into four categories and a few subclasses counting on their wavelength and most output power. This classification was supported the severity of the injury to an individual once exposed to optical device. These categories may be from one to four. a category one optical device is completely not dangerous once used, whereas the category four optical device is that the most dangerous. the present system was the revised system since 2002, before that the recent system was used. within the new system amendments are done to bound styles of lasers having a lower hazard than mentioned within the recent system. supported the output power in an exceedingly specific wavelength, lasers area unit classified. it's essential the proper info on the optical device category, potential hazards and safety directions area unit such as by the instrumentation makers. within the categories 1–4 optical device, there area unit the sub-classes 1M, 2M, 3A and 3B. The new system presently in use (shown in Table 1) uses Arabic numerals (1–4), whereas it had been classified with Roman numerals (I–IV) within the recent system.

Classification supported generating media

Based on the generating media, lasers may be

classified into 3 groups: (1) dioxide (CO2) lasers, (2) metal (Nd) lasers and

(3) metal yttrium-aluminium-garnet (Nd-YAG) lasers (Thawari et al. 2005; Mathew

et al. 1999; Schuocker 1989). The greenhouse emission lasers may be used for

boring, cutting and engraving (Chow et al. 2012; Kan 2014b). greenhouse

emission lasers may be of the four types: (a) quick axial flow, (b) slow axial

flow, (c) cross flow and (d) block lasers (Powell 1993). In quick axial flow, a

combination of greenhouse emission, chemical element (N2) and inert gas (He) is

employed at high speed by a rotary engine. a straightforward blower is employed

for slow axial flow and cross flow lasers. block lasers would like no

pressurization as they add static condition.

The Nd lasers and Nd-YAG

lasers, though similar modish, they're applied in numerous areas (Schuocker

1989). the previous is employed for boring, whereas the later is employed for

engraving. All the optical device categories may be used for fastening.

Generally, greenhouse emission lasers area

unit made by passing the electrical discharge through a airlike mixture excited

by electrical energy (DC) with frequency (RF) energy. This technique is wide

used because the DC-excited styles would like electrodes within the cavity,

thanks to risk of abrasion. Industrial cutting of steel, aluminium, paper,

plastics, wood, and materials may be performed by greenhouse emission lasers.

For cutting metals and ceramics; and scribing Nd-YAG lasers area unit used.

The optical device generator and external

optics would like cooling whereas in use (Choudhury and Shirley 2010). this

will be achieved by a fluid like water by current through a excitation within

the optical device instrumentation. the utilization of water cools the fabric

and removes the rubble. additionally, it helps to attain parallel kerf and

multi-directional cutting at high dicing speeds.

Another variety of

solid-state optical device referred to as “fibre laser” is currently turning

into standard in metal cutting business. This optical device is made from a

solid gain medium while not the utilization of any liquid or gas. the main

advantage of fibre optical device is that the very little spot size. Fibre

lasers, with a wavelength of one.064 µm, will manufacture an especially little

spot size, that makes it ideal for cutting reflective metals.

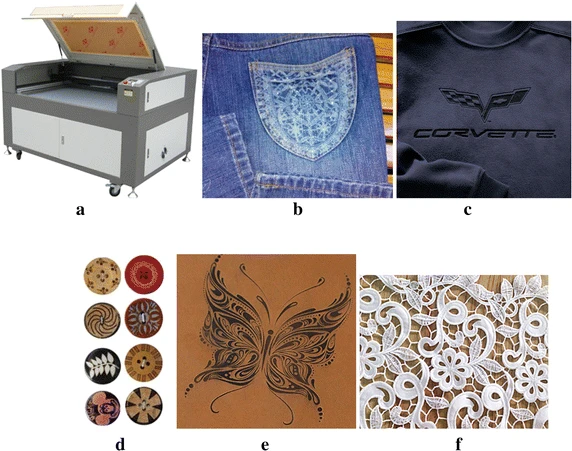

Application of optical device in fashion industry

As Associate in Nursing all-new method, there area unit many applications of optical device in fashion industry. optical device engraving and cutting technologies currently being wide applied in several garment industries, cloth production units, different textile and animal skin industries (Choudhury and Shirley 2010; Nayak and Khandual 2010). numerous applications of optical device area unit mentioned within the following section.

Fabric fault detection

When cloth is received at the stores of a garment production unit, the faults within the cloth may be detected with morphological image process supported optical device (Mallik-Goswami and Datta 2000; Ribolzi et al. 1993; Mursalin et al. 2005). Laser-based optical Fourier rework analysis may be used for fault detection within the cloth because the pattern is recurrent at regular intervals. {the cloth|the material} is concentrated with a optical device and therefore the optical phenomenon gratings obtained from the regularity of longitudinal and cross threads within the fabric area unit superimposed. A Fourier lens is employed to supply the optical phenomenon pattern of the material. A second Fourier lens with same focal distance magnifies and inverts the check sample image. A charge-coupled device (CCD) camera is employed to capture the image. the information is transferred and hold on in an exceedingly laptop. the pc programming helps in comparison the noninheritable pictures with the hold on pictures by changing the image into binary mode. A fault is reported once the measured parameter is deviating from the quality. The severity of the fault depends upon the number of deviation from the quality.

Laser cutting

After they were introduced within the nineteenth century, the style designers area unit wide adopting optical device cutting in garment producing (Petrak and Rogale 2001). In artificial materials, optical device cutting produces well-finished edges because the optical device melts and fuses the sting, that avoids the matter of fraying made by typical knife cutters. what is more, use of optical device cutting is more and more used for animal skin thanks to the preciseness of cut parts. In fashion accessories like jewelry, optical device cutting may be accustomed manufacture new and strange styles to supply a fusion of attire style and jewelry vogue.

In optical device cutting a optical device is employed to chop the material into the required pattern shapes. a really fine optical device is concentrated on to the material surface, that will increase the temperature well and cutting takes place thanks to vaporization. commonly gas lasers (CO2) area unit used for cutting of cloth. The cutting machine (Fig. 2) includes a supply of optical device, a cutting head fitted with mirrors to mirror the light beam to the cutting line, a laptop to regulate the whole system and an acceptable mean for removing the cut elements. the appliance of inert gases (N2, He) throughout cutting prevents the charring and removes rubble and smoke from the cutting space. just like the mechanical cutting devices, a light beam doesn't become blunt and want sharpening. Automatic single ply optical device cutters area unit quicker (30–40 m/min) than automatic multiple ply knife cutters (5–12 m/min). However, whereas cutting multiple plies, knife cutters area unit quicker per garment cut and conjointly cheaper.

The limitation of optical

maser cutting is that the range of lays of the material which will be cut by

the beam. Best result's obtained whereas cutting single or a couple of lays,

however the accuracy and exactitude isn't obtained with many plies.

additionally there's an opportunity of the cut edges to be united along

particularly just in case of synthetics. In some cases the waterproofing of the

perimeters of cut patterns and stitched garment elements is crucial to

forestall fraying, wherever the optical maser plays the role. As in garment

production facilities stress is given in multiple lay cutting, the optical

maser cutting appears unlikely to become widespread. However, it's with success

employed in cutting of sails wherever single ply cutting is that the norm and a

small fusing of the sting of synthetics and woven materials is fascinating.

additionally, optical maser cutting is employed in some areas of home

furnishing.

Laser cutting is cheaper compared with the

standard cutting strategies (Mahrle and Beyer 2009). what is more, because the

optical maser cutting doesn’t have mechanical action, high exactitude of the

cut elements at high cutting speed area unit possible (Mathew et al. 1999). The

optical maser cutters area unit safer and embrace easy maintenance options,

which might be operated for extended length. The optical maser cutters is

integrated to the pc technology. It will manufacture the product at identical

time once coming up with within the laptop. optical maser cutting machines have

quicker speed and less complicated operation.

Laser cutting machines area unit appropriate

for cutting textile materials, composites and lather materials (Caprino and

Tagliaferri 1988; Steen et al. 2010; Cenna and Mathew 2002). they'll operate

for a large vary of material, that isn't attainable with die cutters. Hence,

optical maser cutting machines area unit step by step been accepted in garment

producing. The options of optical maser applications include: - Laser marking, optical maser

engraving and optical maser cutting combined in one step

- No mechanical wear,

therefore sensible quality

- No fixation of fabric is

needed thanks to force-free process

- No material fraying in artificial fibres

thanks to formation of united edges

- It is clean and lint-free

- Simple method thanks to integrated laptop

style

- High quality raw materials

and important price saving

- Extremely high exactitude in cutting contours

- High operating speed

Contactless,

- wear-free technique

- No chips, less waste

Objective analysis of seam pucker

Garment look greatly influences garment quality. Seam pucker negatively affects the garment look (Nayak and Padhye 2014b, 2015a; Nayak et al. 2010, 2013; Fan and Liu 2000). There area unit many strategies to live seam pucker, however the standard scoring system developed by yankee Association of Textile Chemists and Colourists (AATCC) is especially used. The light beam will live the degree of puckering in clothes by geometrical models. during this technique a seam within the garment is scanned by a 3D optical maser scanner by golf shot the garment on a dummy. The optical maser head is captive to ANy 3D area inside a confined place by an operator. it's attainable to scan the target object from completely different angles. A pucker profile of the scanned seam is obtained by process the image with a 2nd digital filter. Physical parameters like like (σ is variance) is obtained from the pucker profile, which might then be linearly associated with grade for seam pucker. From the objectively measured log σ2, the pucker grade is objectively evaluated.

Mass customization

The term mass customization

is employed once custom-fit clothes area unit obtained looking on the body

dimensions and individual’s alternative. The terribly very first thing to mass

customise clothes is that the correct measurements of individual’s body (Nayak

and Padhye et al. 2015a). optical maser scanning technology is one among the

numerous techniques used for mensuration. optical maser scanning technology

uses one or multiple skinny and sharp stripe lasers to live body size. Cameras

also are accustomed acquire the scene and assist the optical maser scanner. The

body measurements area unit derived by applying easy geometrical rules

(D’Apuzzo 2007; Tong et al. 2012; Ashdown et al. 2004). so as to verify the

harmlessness of the beam, solely eye-safe lasers is used. further optical

devices like mirrors is accustomed assist one light beam. The optical maser

scanning unit (Fig. 3) consisting of sunshine sensors and optical systems

focuses on the build for digitization. the quantity of sunshine sensors and optical

systems will vary as per the positions of the body. as an example, Vitronic1

body scanner consists of 3 scanning units which will synchronously move

vertically on 3 pillars.

Laser-based denim attenuation

Now the age of attenuation of denim by sandblasting

is changing into older because the new technology of optical maser attenuation

is exchange it (Ortiz-Morales et al. 2003; Tarhan and Sarıışık 2009). In

optical maser attenuation, a laptop drives the light beam to the fabric

wherever marking or attenuation is needed. The light beam decomposes the dye

and also the ensuing vapors area unit ventilated away. the fabric fades solely

wherever the beam impacts on the material. Commercially 2 kinds of lasers area

unit being used: solid primarily {based} (wavelength of one μm) and gas based

(wavelength of ten μm). the required degree of attenuation depends upon the

wavelength, power density, and pulse dimension of the light beam. the tactic of

marking or attenuation by optical maser is additional environmental friendly as

compared to acid laundry or sandblasting (Kan et al. 2010). A laser-faded denim

sample is shown within the Fig. 4.

Laser engraving

In optical maser engraving optical maser is

employed to mark or engrave AN object. the method is incredibly advanced, and

sometimes processed systems area unit accustomed drive the optical maser head

(Kan et al. 2010; Juciene et al. 2013). In spite of the quality, terribly

precise and clean engravings is obtained with high rate of production. The

technique doesn't involve physical contact with the engraving surface, hence,

no wear and tear. The marks created by optical maser engraving area unit clean,

crisp and permanent. additionally, lasers area unit quicker than different

standard strategies used for product acquisition, that provides bigger

skillfulness in material choice. One machine is accustomed pass over skinny

materials further as build engravings on them. optical maser engraving is

employed to engrave the printing screens, for hollowing, for making pattern buttons,

to engrave animal skin, denim etc. (Fig. 5). Pictures, flower patterns and even

customized signatures is carven on animal skin shoes, animal skin bag, wallet,

animal skin belt, animal skin lounge and animal skin garments, greatly

increasing the else worth of product. additionally optical maser engraving is

employed to form adorned pattern within the material by color attenuation and

burning the materials. The low price sealed carbonic acid gas optical masers

area unit most well-liked for laser engraving.

Denim engraving is another invasive

application of optical maser victimization sealed carbonic acid gas lasers

(Juciene et al. 2013; Kan 2014a). The optical maser is employed to form minute

styles and patterns on denim material further as finished denims. This technic

is employed in place of the standard techniques like sandblasting and acid

laundry. The accuracy and style flexibility is incredibly wide, that can’t be

achieved by the standard strategies. Lasers will manufacture 3D effects by

techniques like embroidering, embossing, or perhaps apparent cuts, tears and

mends. Any image that's created in an exceedingly laptop assisted style (CAD),

is transferred to denim by appropriate optical maser method. whereas

victimization lasers, options like sensible mode quality, high power stability,

time period management of optical maser power and quick pulse rise-time area

unit the vital parameters which will cause color modification while not

charring or different harm to the material. Such harm may scale back the

merchandise life and cosmetically unacceptable. the benefits of optical maser

engraving over ancient strategies include:

High operating speed while

not mechanical contact

No wear and tear of elements

Reduced waste

Complete exhaust and filtering

Exact contours attainable

Welded garment production

Welding is another method of change of integrity materials for garment production wherever the thermoplastic materials area unit joined along by the applying of warmth. the warmth is provided by unhearable or by high powerful optical maser (Petrie 2015). The welded garment although weaker than the stitched counterpart, offers higher look because it doesn't contain large seam and is additional versatile.

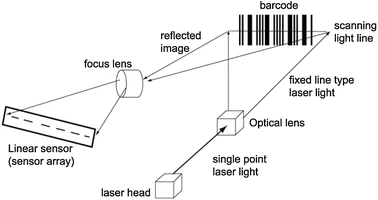

Bar code scanning

The scanners accustomed scan

the barcodes for product identification generally uses helium–neon (He–Ne)

lasers. The light beam bounces out of a rotating mirror whereas scanning the

code. This sends a modulated beam to a laptop, that contains the merchandise

data. Semiconductor based-lasers also can be used for this purpose. However, a

number of the recent makers area unit victimization frequency Identification

(RFID) based mostly tags rather than barcodes thanks to bound blessings (Nayak

and Padhye 2014c). The RFID tag is processed quickly and it avoids the physical

handling of the merchandise as in barcode systems (Nayak et al. 2007, Nayak et

al. 2015b; Nayak and Padhye 2015b). The mechanism of a code scanner is shown in

Fig. 6.

Comments

Post a Comment